Work Ahead™ Investor Presentation January 2020 Work Ahead.

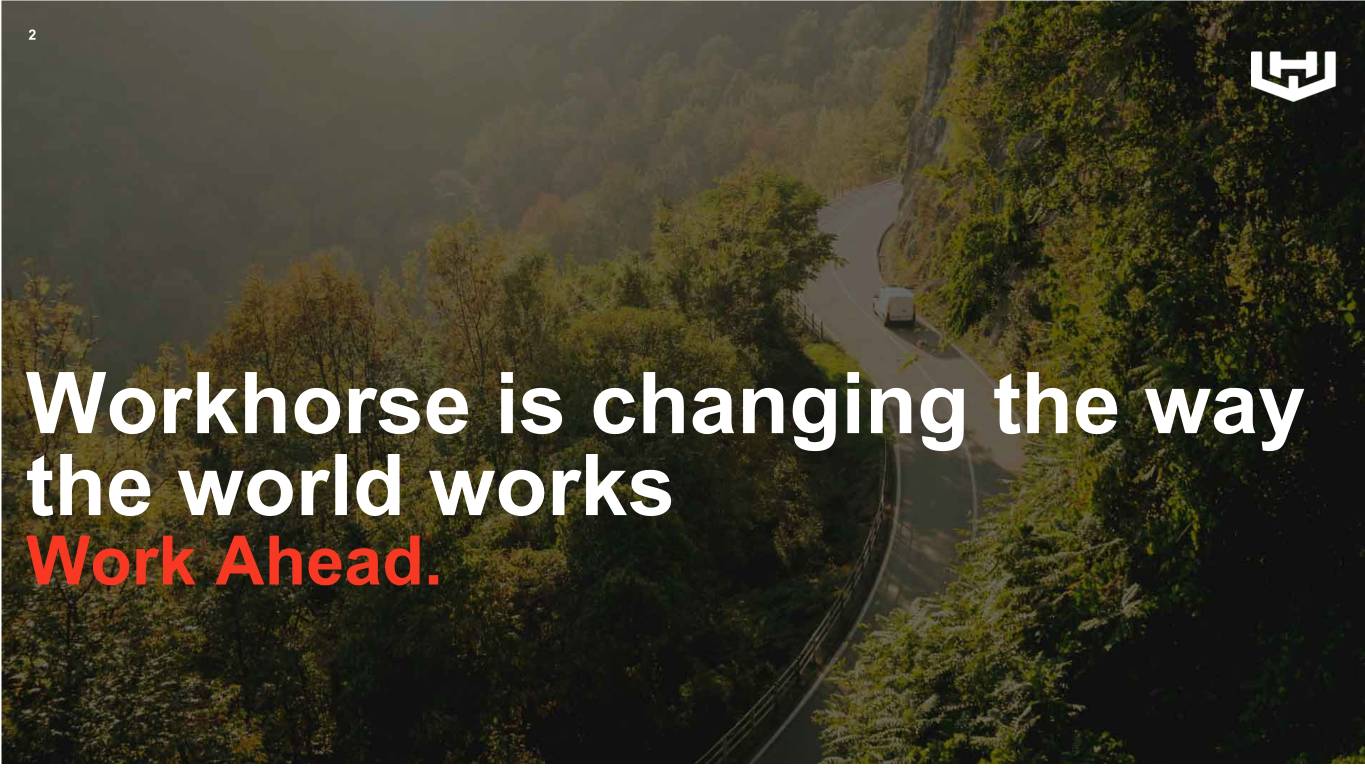

22 Workhorse is changing the way the world works Work Ahead. Work Ahead.

3 Cautionary Note Regarding Forward Looking Statements This presentation includes forward-looking statements. These statements are made under the "safe harbor" provisions of the U.S. Private Securities Litigation Reform Act of 1995. These statements may be identified by words such as "believes," "expects," "anticipates," "estimates," "projects," "intends," "should," "seeks," "future," "continue," or the negative of such terms, or other comparable terminology. Forward-looking statements are statements that are not historical facts. Such forward-looking statements are subject to risks and uncertainties, which could cause actual results to differ materially from the forward-looking statements contained herein. Factors that could cause actual results to differ materially include, but are not limited to: our limited operations and need to expand in the near future to fulfill product orders; risks associated with obtaining orders and executing upon such orders; the ability to protect our intellectual property; the potential lack of market acceptance of our products; potential competition; our inability to retain key members of our management team; our inability to raise additional capital to fund our operations and business plan; our inability to maintain our listing of our securities on the Nasdaq Capital Market; our ability to continue as a going concern; our liquidity and other risks and uncertainties and other factors discussed from time to time in our filings with the Securities and Exchange Commission ("SEC"), including our annual report on Form 10-K filed with the SEC. Workhorse expressly disclaims any obligation to publicly update any forward-looking statements contained herein, whether as a result of new information, future events or otherwise, except as required by law. Work Ahead.

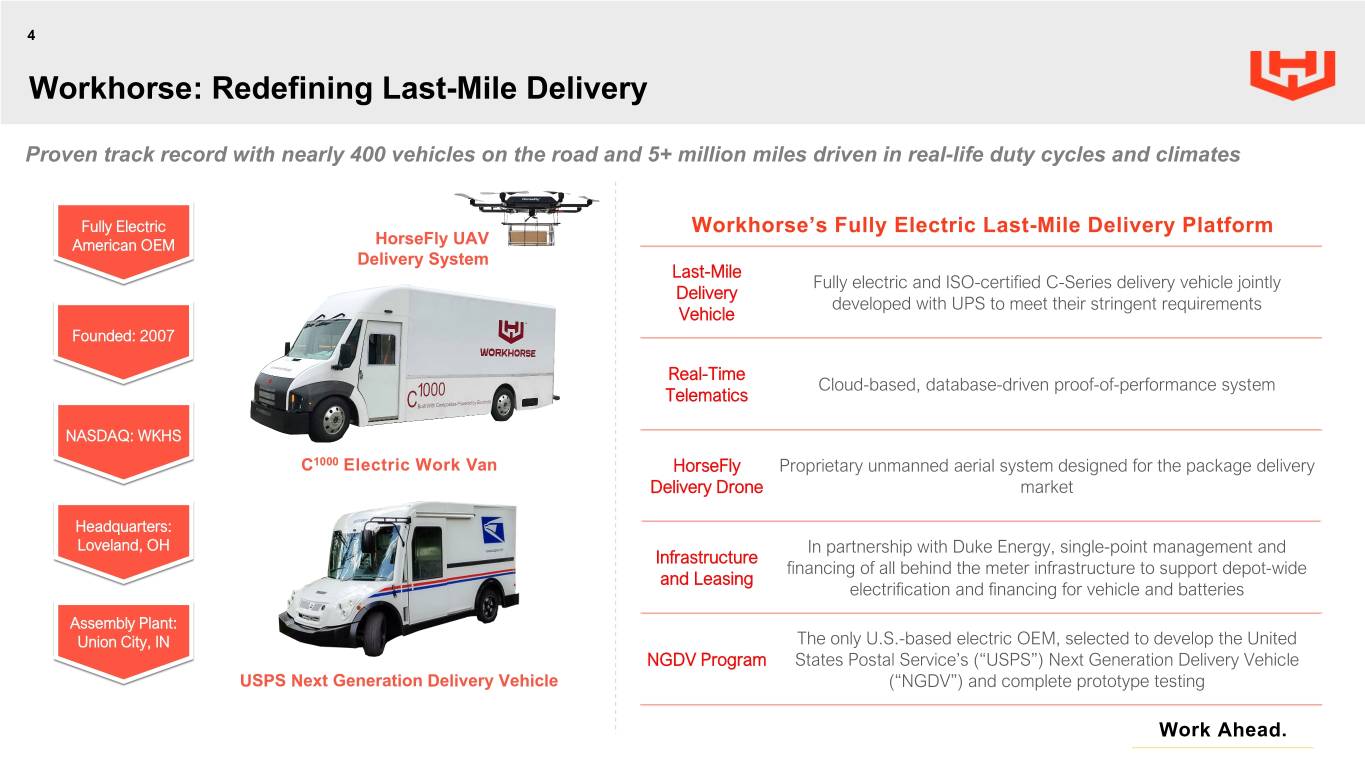

4 Workhorse: Redefining Last-Mile Delivery Proven track record with nearly 400 vehicles on the road and 5+ million miles driven in real-life duty cycles and climates Fully Electric Workhorse’s Fully Electric Last-Mile Delivery Platform American OEM HorseFly UAV Delivery System Last-Mile Fully electric and ISO-certified C-Series delivery vehicle jointly Delivery developed with UPS to meet their stringent requirements Vehicle Founded: 2007 Real-Time Cloud-based, database-driven proof-of-performance system Telematics NASDAQ: WKHS C1000 Electric Work Van HorseFly Proprietary unmanned aerial system designed for the package delivery Delivery Drone market Headquarters: Loveland, OH In partnership with Duke Energy, single-point management and Infrastructure financing of all behind the meter infrastructure to support depot-wide and Leasing electrification and financing for vehicle and batteries Assembly Plant: Union City, IN The only U.S.-based electric OEM, selected to develop the United NGDV Program States Postal Service’s (“USPS”) Next Generation Delivery Vehicle USPS Next Generation Delivery Vehicle (“NGDV”) and complete prototype testing Work Ahead.

5 Investment Highlights 1 Market leader, first mover and only U.S. pure play OEM in medium duty electrification for last-mile delivery in ~$18B delivery/ cargo van market with significant EV demand 2 Full turnkey solution offers a premier product and vehicle financing through partnership with Duke Energy – proven economics and value proposition with comparable acquisition costs to ICE/diesel vehicles enables positive ROI at ~3 years without incentives 3 Technology validation from blue chip customers and partners 4 Proprietary platform technologies (battery, drive train, chassis, software, telematics) leveraged across vehicle portfolio supported by 7 granted and 4 pending patents 5 Near-term growth opportunities from the USPS NGDV program, which represents a $6.3 billion, 165,000-vehicle opportunity, and partnership with Lordstown Motors Corp. for the development of an all-new fully electric pickup truck 6 Scalable manufacturing at our ~265,000 ft2 plant in Union City, Indiana, with the ability to produce 60,000+ vehicles per year, enables clear path to profitability Work Ahead.

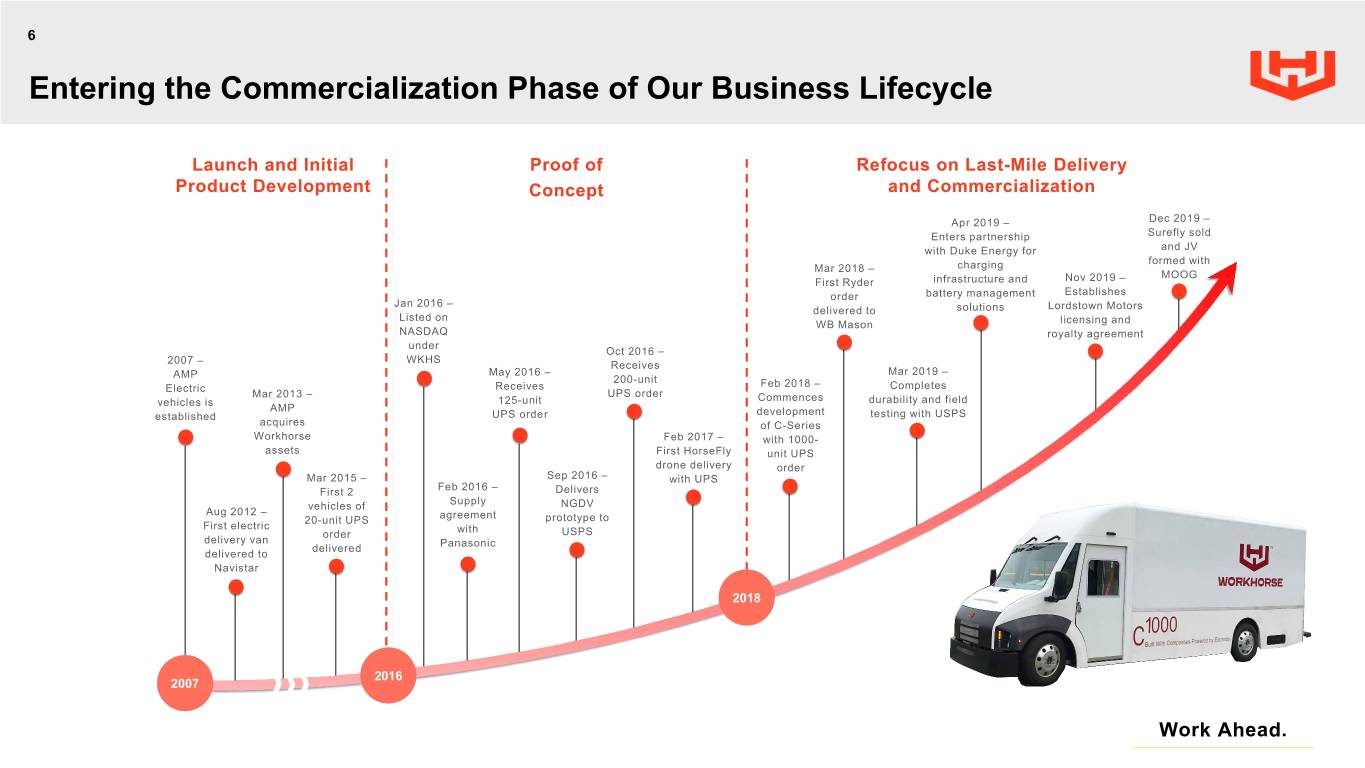

6 Entering the Commercialization Phase of Our Business Lifecycle Launch and Initial Proof of Refocus on Last-Mile Delivery Product Development Concept and Commercialization Apr 2019 – Dec 2019 – Enters partnership Surefly sold with Duke Energy for and JV formed with Mar 2018 – charging MOOG First Ryder infrastructure and Nov 2019 – order battery management Establishes Jan 2016 – delivered to solutions Lordstown Motors Listed on WB Mason licensing and NASDAQ royalty agreement under Oct 2016 – WKHS 2007 – Receives May 2016 – Mar 2019 – AMP 200-unit Electric Receives Feb 2018 – Completes Mar 2013 – UPS order vehicles is 125-unit Commences durability and field AMP established UPS order development testing with USPS acquires of C-Series Workhorse Feb 2017 – with 1000- assets First HorseFly unit UPS drone delivery order Mar 2015 – Sep 2016 – with UPS First 2 Feb 2016 – Delivers vehicles of Supply NGDV Aug 2012 – 20-unit UPS agreement prototype to First electric order with USPS delivery van delivered Panasonic delivered to Navistar 2018 2016 2007 Work Ahead.

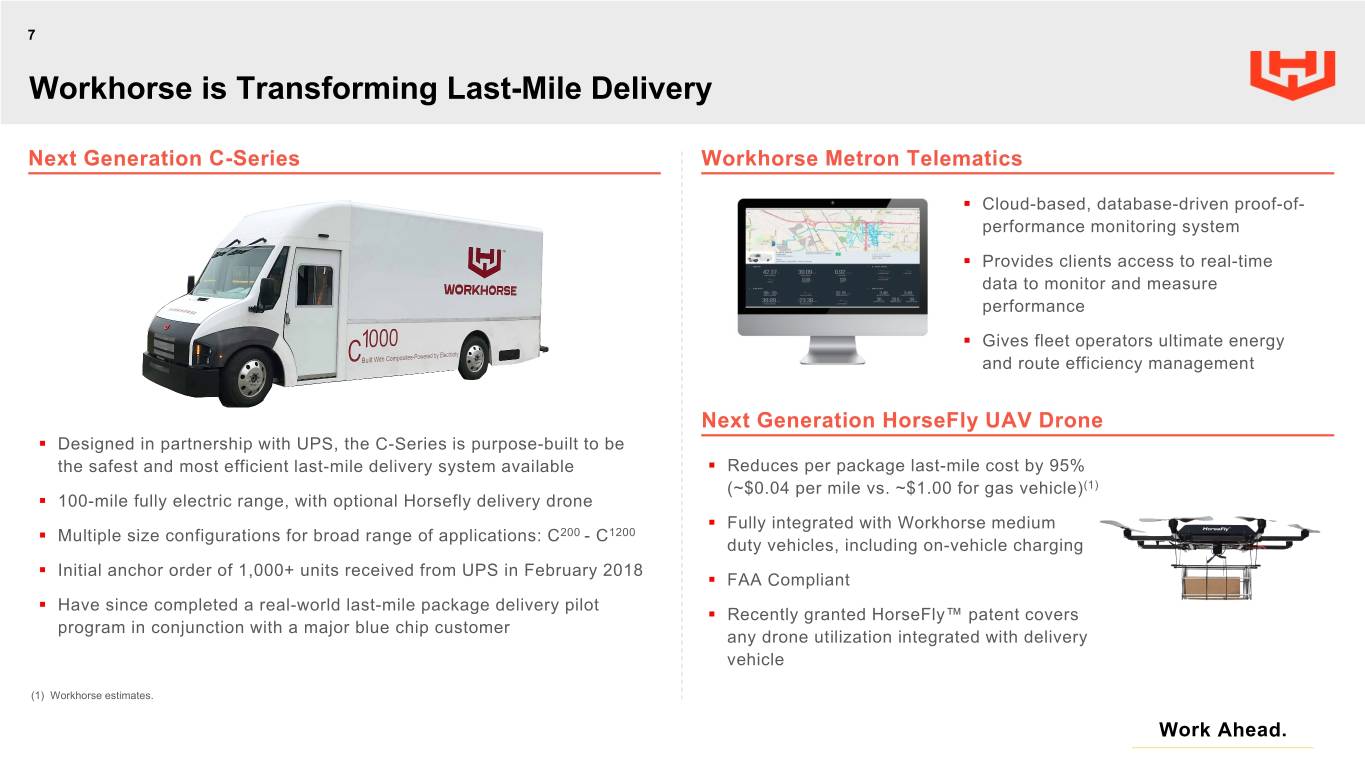

7 Workhorse is Transforming Last-Mile Delivery Next Generation C-Series Workhorse Metron Telematics . Cloud-based, database-driven proof-of- performance monitoring system . Provides clients access to real-time data to monitor and measure performance . Gives fleet operators ultimate energy and route efficiency management Next Generation HorseFly UAV Drone . Designed in partnership with UPS, the C-Series is purpose-built to be the safest and most efficient last-mile delivery system available . Reduces per package last-mile cost by 95% (~$0.04 per mile vs. ~$1.00 for gas vehicle)(1) . 100-mile fully electric range, with optional Horsefly delivery drone . Fully integrated with Workhorse medium . Multiple size configurations for broad range of applications: C200 - C1200 duty vehicles, including on-vehicle charging . Initial anchor order of 1,000+ units received from UPS in February 2018 . FAA Compliant . Have since completed a real-world last-mile package delivery pilot . Recently granted HorseFly™ patent covers program in conjunction with a major blue chip customer any drone utilization integrated with delivery vehicle (1) Workhorse estimates. Work Ahead.

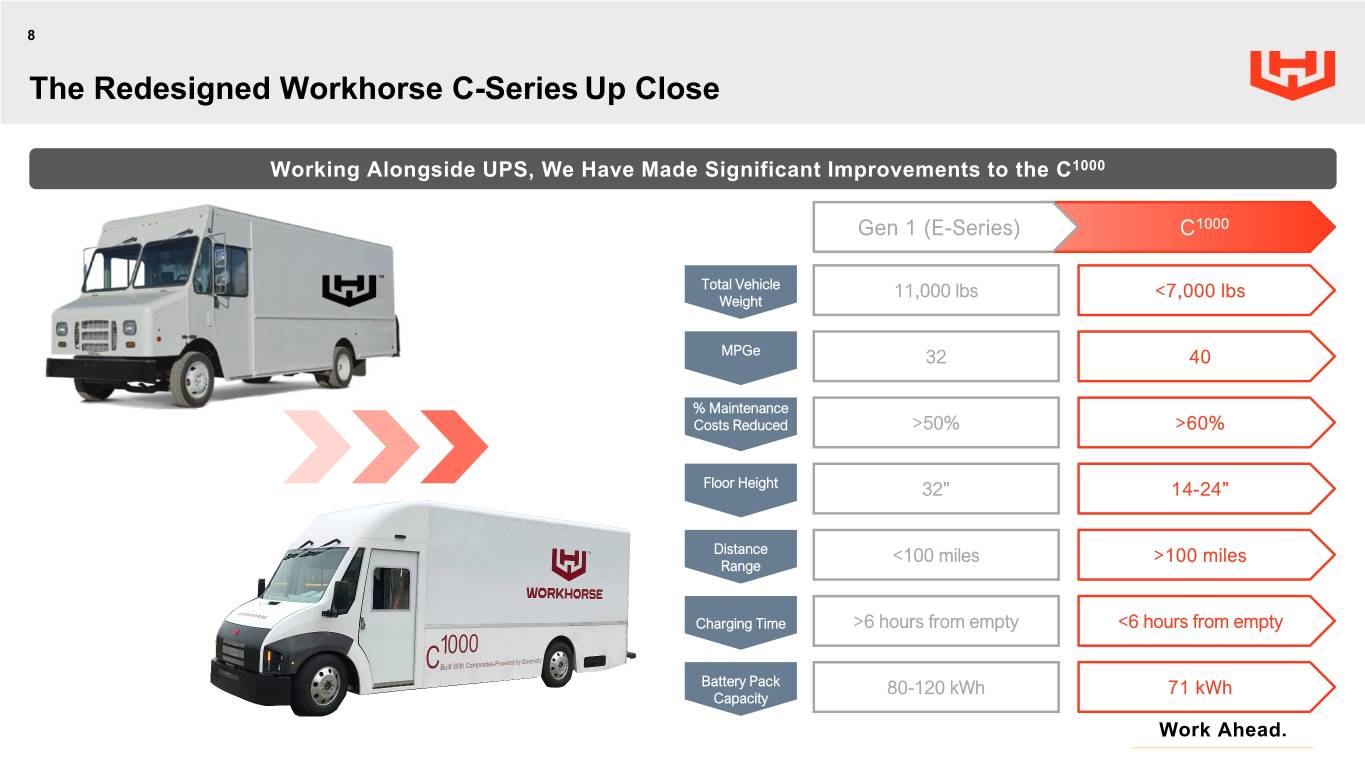

8 The Redesigned Workhorse C-Series Up Close Working Alongside UPS, We Have Made Significant Improvements to the C1000 Gen 1 (E-Series) C1000 Total Vehicle 11,000 lbs <7,000 lbs Weight MPGe 32 40 % Maintenance Costs Reduced >50% >60% Floor Height 32” 14-24” Distance <100 miles >100 miles Range Charging Time >6 hours from empty <6 hours from empty Battery Pack 80-120 kWh 71 kWh Capacity Work Ahead.

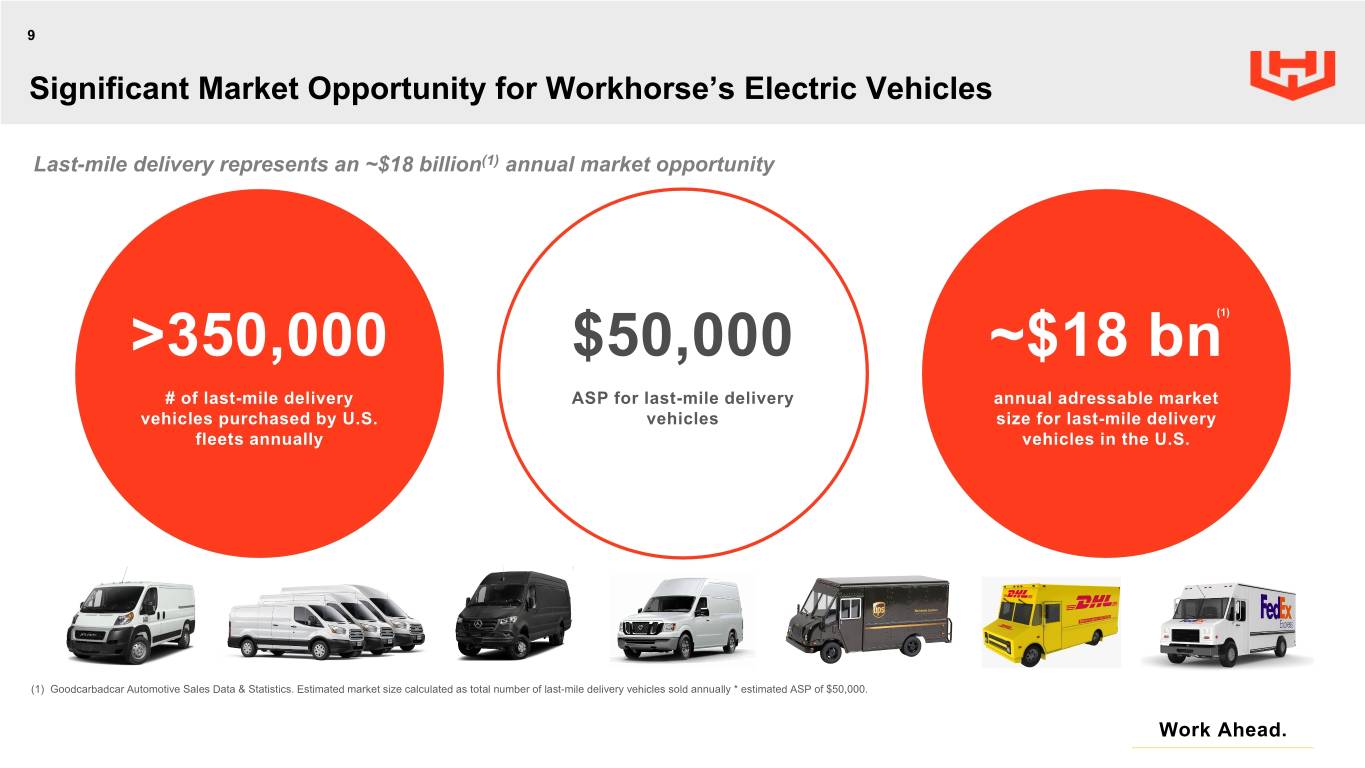

9 Significant Market Opportunity for Workhorse’s Electric Vehicles Last-mile delivery represents an ~$18 billion(1) annual market opportunity (1) >350,000 $50,000 ~$18 bn # of last-mile delivery ASP for last-mile delivery annual adressable market vehicles purchased by U.S. vehicles size for last-mile delivery fleets annually vehicles in the U.S. (1) Goodcarbadcar Automotive Sales Data & Statistics. Estimated market size calculated as total number of last-mile delivery vehicles sold annually * estimated ASP of $50,000. Work Ahead.

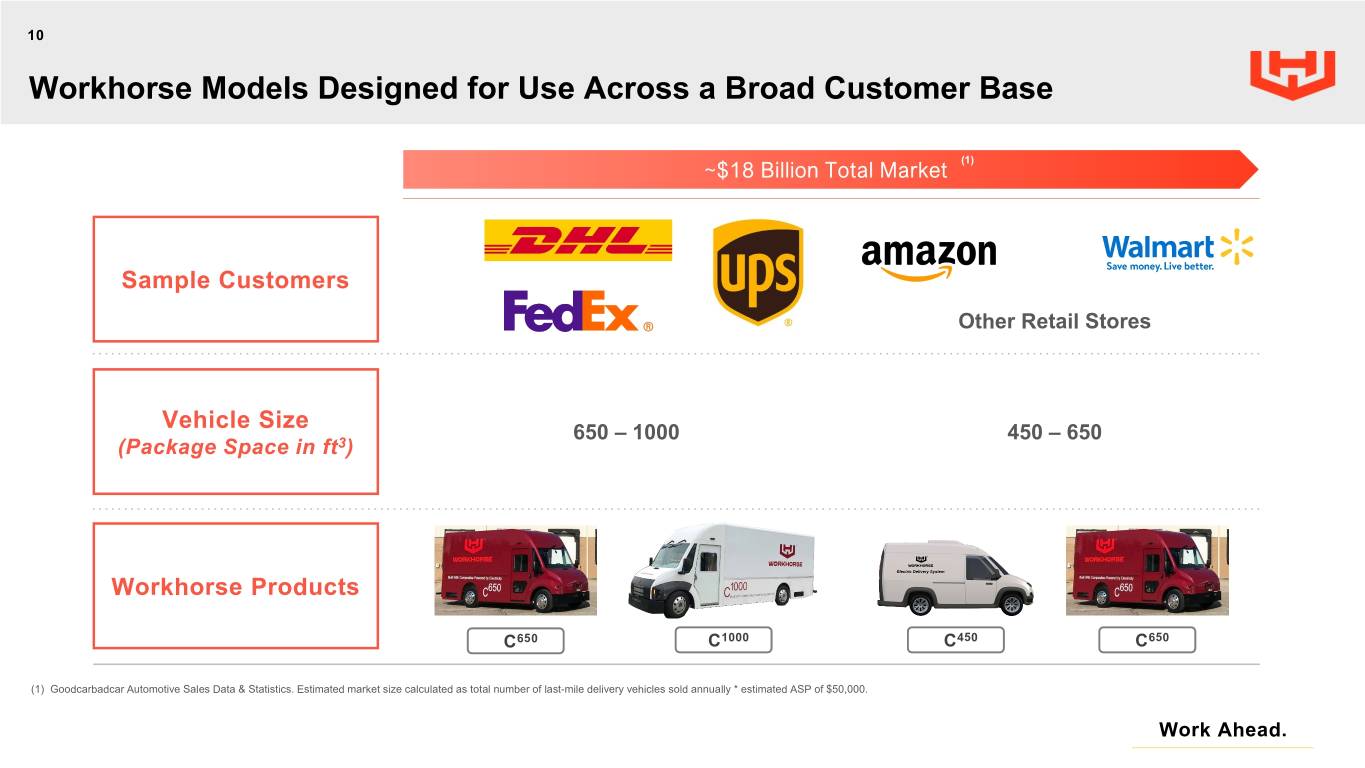

10 Workhorse Models Designed for Use Across a Broad Customer Base ~$18 Billion Total Market (1) Sample Customers Other Retail Stores Vehicle Size 650 – 1000 450 – 650 (Package Space in ft3) Workhorse Products C650 C1000 C450 C650 (1) Goodcarbadcar Automotive Sales Data & Statistics. Estimated market size calculated as total number of last-mile delivery vehicles sold annually * estimated ASP of $50,000. Work Ahead.

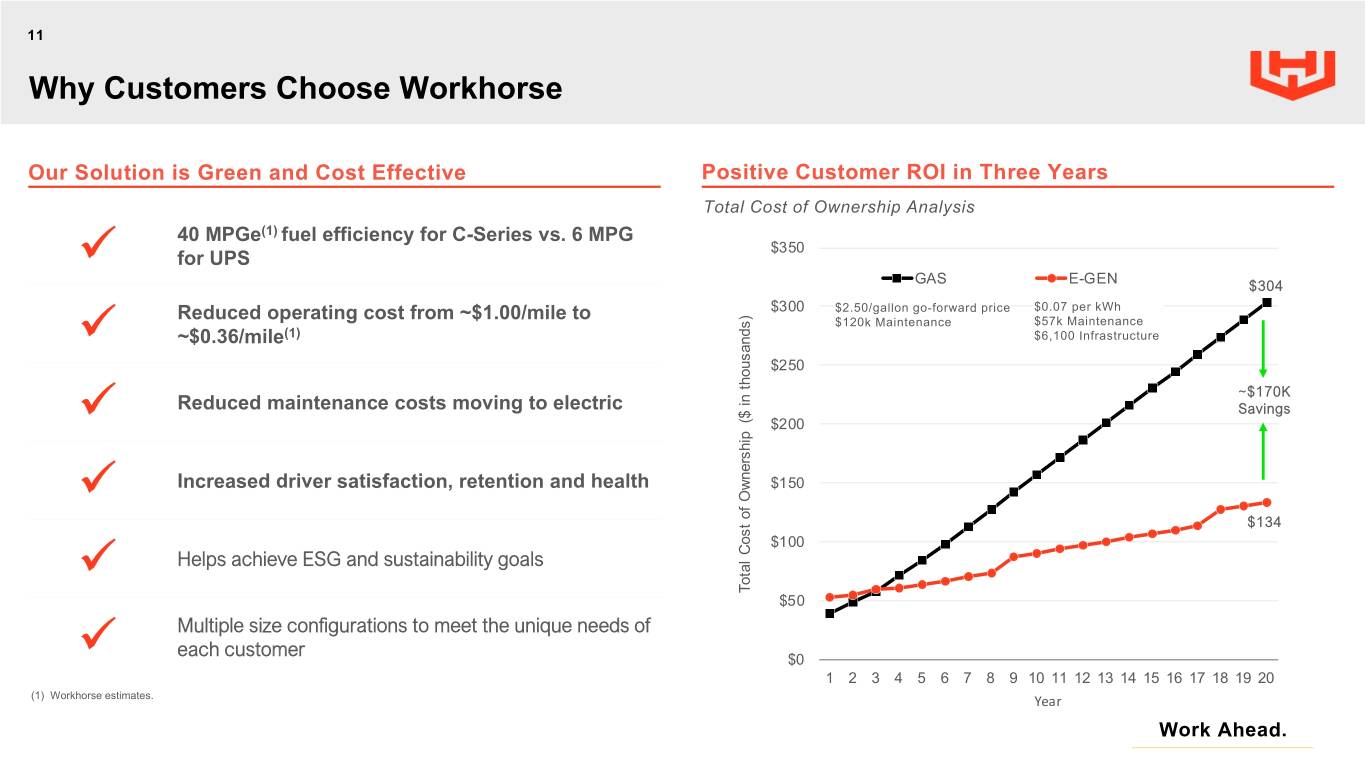

11 Why Customers Choose Workhorse Our Solution is Green and Cost Effective Positive Customer ROI in Three Years Total Cost of Ownership Analysis 40 MPGe(1) fuel efficiency for C-Series vs. 6 MPG $350 for UPS GAS E-GEN $304 $300 $2.50/gallon go-forward price $0.07 per kWh Reduced operating cost from ~$1.00/mile to $120k Maintenance $57k Maintenance ~$0.36/mile(1) $6,100 Infrastructure $250 ~$170K Reduced maintenance costs moving to electric Savings $200 Increased driver satisfaction, retention and health $150 $134 $100 Helps achieve ESG and sustainability goals Total Cost of Ownership in ($ thousands) $50 Multiple size configurations to meet the unique needs of each customer $0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 (1) Workhorse estimates. Year Work Ahead.

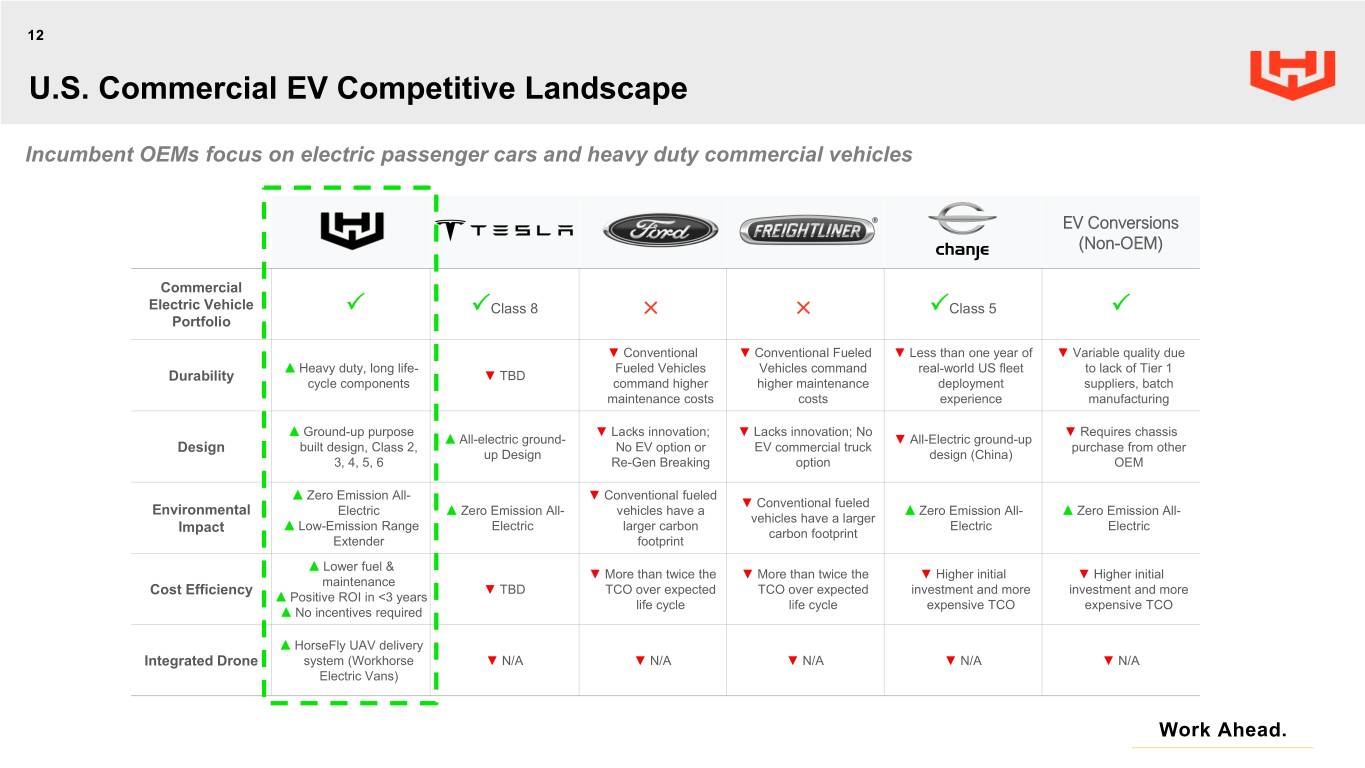

12 U.S. Commercial EV Competitive Landscape Incumbent OEMs focus on electric passenger cars and heavy duty commercial vehicles EV Conversions (Non-OEM) Commercial Electric Vehicle Class 8 × × Class 5 Portfolio ▼ Conventional ▼ Conventional Fueled ▼ Less than one year of ▼ Variable quality due ▲ Heavy duty, long life- Fueled Vehicles Vehicles command real-world US fleet to lack of Tier 1 ▼ TBD Durability cycle components command higher higher maintenance deployment suppliers, batch maintenance costs costs experience manufacturing ▲ Ground-up purpose ▼ Lacks innovation; ▼ Lacks innovation; No ▼ Requires chassis ▲ All-electric ground- ▼ All-Electric ground-up built design, Class 2, No EV option or EV commercial truck purchase from other Design up Design design (China) 3, 4, 5, 6 Re-Gen Breaking option OEM ▲ Zero Emission All- ▼ Conventional fueled ▼ Conventional fueled Environmental Electric ▲ Zero Emission All- vehicles have a ▲ Zero Emission All- ▲ Zero Emission All- vehicles have a larger ▲ Low-Emission Range Electric larger carbon Electric Electric Impact carbon footprint Extender footprint ▲ Lower fuel & ▼ More than twice the ▼ More than twice the ▼ Higher initial ▼ Higher initial maintenance ▼ TBD TCO over expected TCO over expected investment and more investment and more Cost Efficiency ▲ Positive ROI in <3 years life cycle life cycle expensive TCO expensive TCO ▲ No incentives required ▲ HorseFly UAV delivery Integrated Drone system (Workhorse ▼ N/A ▼ N/A ▼ N/A ▼ N/A ▼ N/A Electric Vans) Work Ahead.

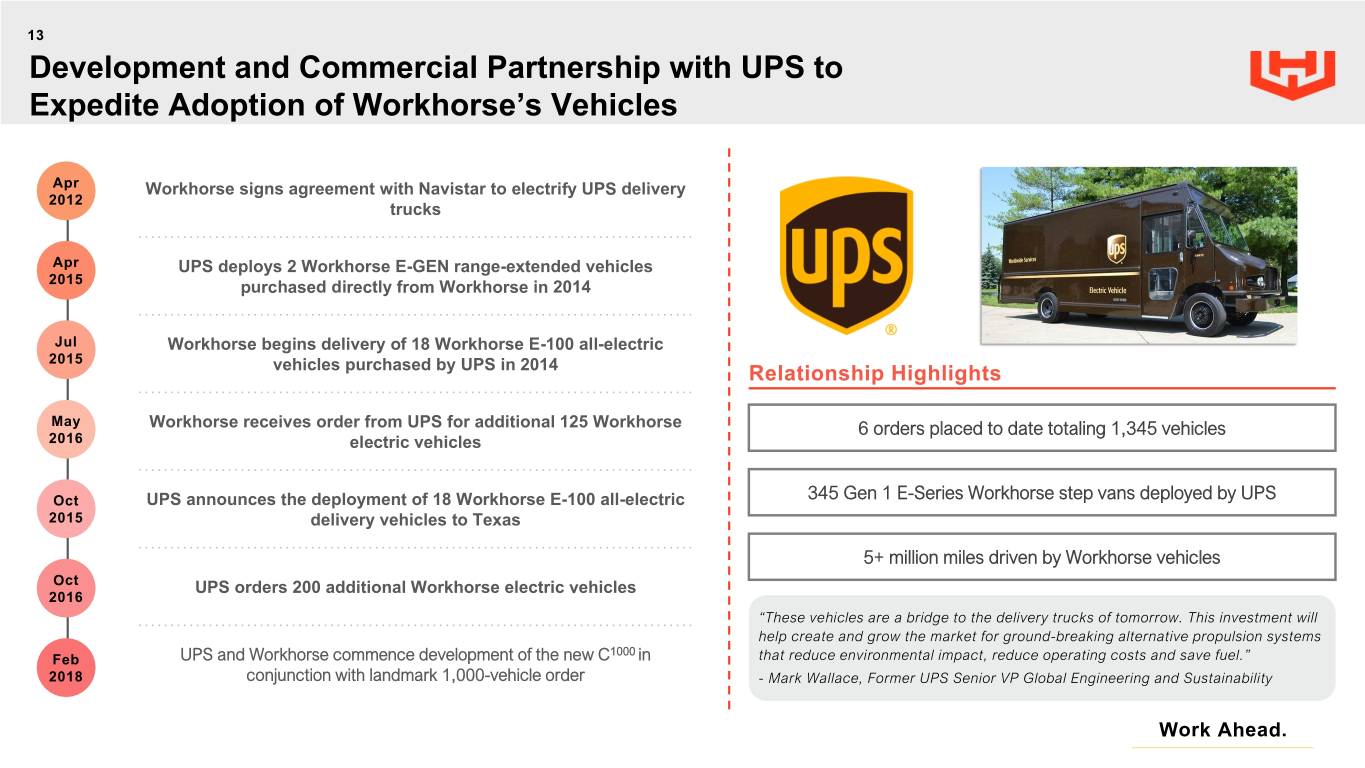

13 Development and Commercial Partnership with UPS to Expedite Adoption of Workhorse’s Vehicles Apr Workhorse signs agreement with Navistar to electrify UPS delivery 2012 trucks Apr UPS deploys 2 Workhorse E-GEN range-extended vehicles 2015 purchased directly from Workhorse in 2014 Jul Workhorse begins delivery of 18 Workhorse E-100 all-electric 2015 vehicles purchased by UPS in 2014 Relationship Highlights May Workhorse receives order from UPS for additional 125 Workhorse 6 orders placed to date totaling 1,345 vehicles 2016 electric vehicles 345 Gen 1 E-Series Workhorse step vans deployed by UPS Oct UPS announces the deployment of 18 Workhorse E-100 all-electric 2015 delivery vehicles to Texas 5+ million miles driven by Workhorse vehicles Oct UPS orders 200 additional Workhorse electric vehicles 2016 “These vehicles are a bridge to the delivery trucks of tomorrow. This investment will help create and grow the market for ground-breaking alternative propulsion systems 1000 Feb UPS and Workhorse commence development of the new C in that reduce environmental impact, reduce operating costs and save fuel.” 2018 conjunction with landmark 1,000-vehicle order - Mark Wallace, Former UPS Senior VP Global Engineering and Sustainability Work Ahead.

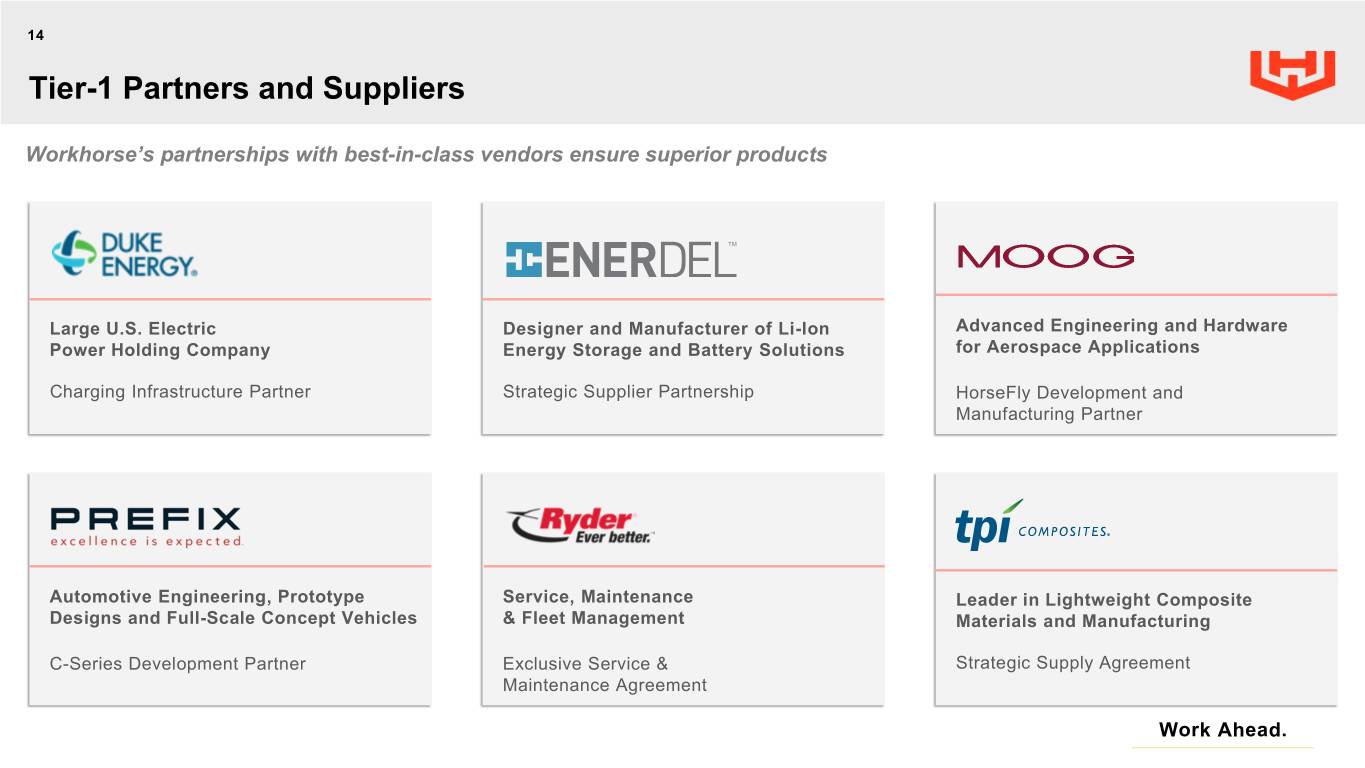

14 Tier-1 Partners and Suppliers Workhorse’s partnerships with best-in-class vendors ensure superior products Large U.S. Electric Designer and Manufacturer of Li-Ion Advanced Engineering and Hardware Power Holding Company Energy Storage and Battery Solutions for Aerospace Applications Charging Infrastructure Partner Strategic Supplier Partnership HorseFly Development and Manufacturing Partner Automotive Engineering, Prototype Service, Maintenance Leader in Lightweight Composite Designs and Full-Scale Concept Vehicles & Fleet Management Materials and Manufacturing C-Series Development Partner Exclusive Service & Strategic Supply Agreement Maintenance Agreement Work Ahead.

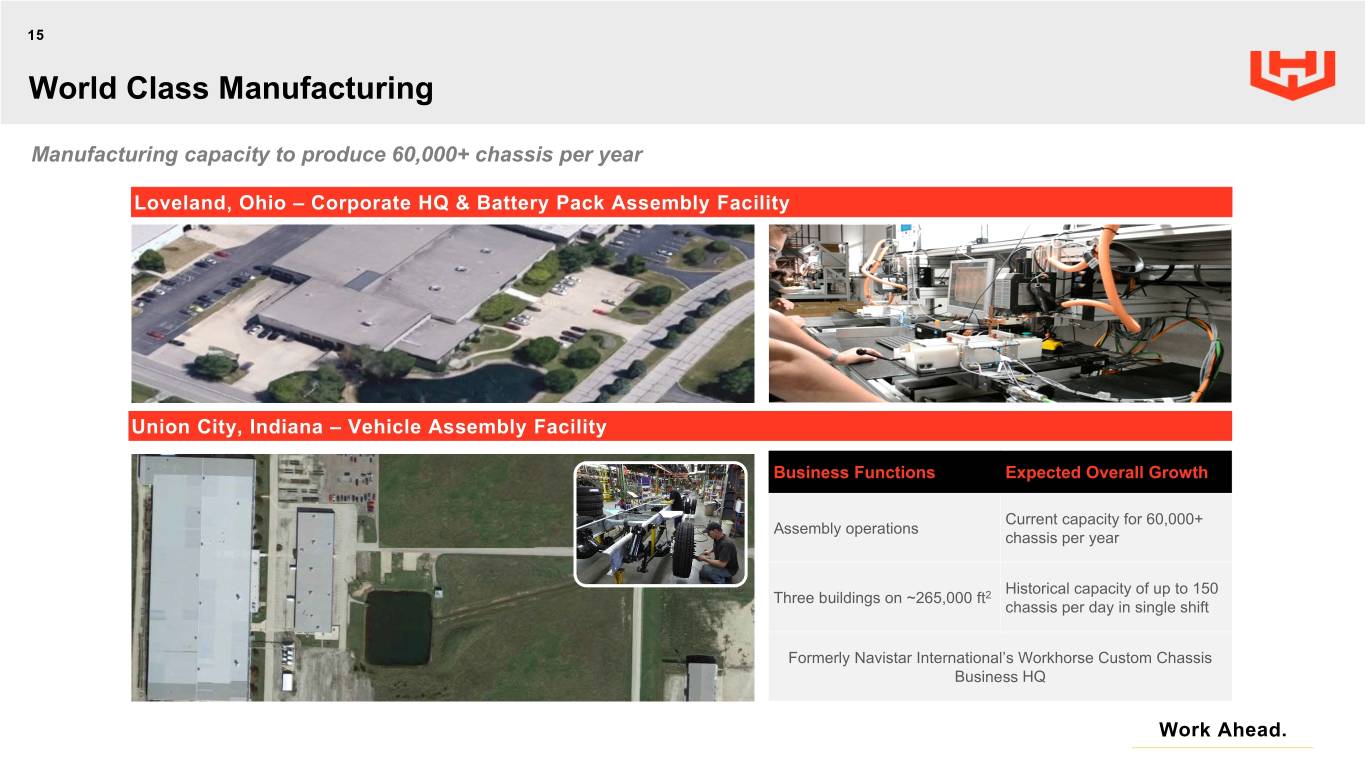

15 World Class Manufacturing Manufacturing capacity to produce 60,000+ chassis per year Loveland, Ohio – Corporate HQ & Battery Pack Assembly Facility Union City, Indiana – Vehicle Assembly Facility Business Functions Expected Overall Growth Current capacity for 60,000+ Assembly operations chassis per year Historical capacity of up to 150 Three buildings on ~265,000 ft2 chassis per day in single shift Formerly Navistar International’s Workhorse Custom Chassis Business HQ Work Ahead.

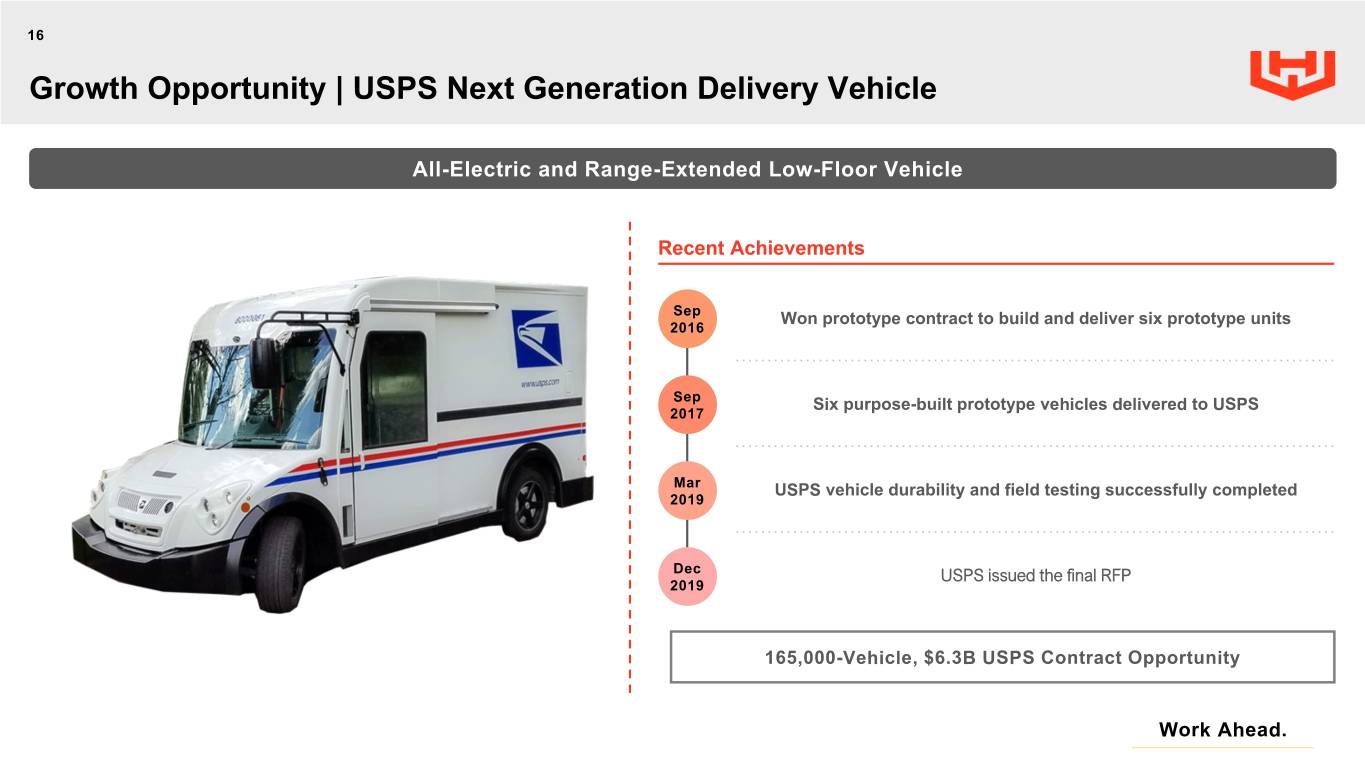

16 Growth Opportunity | USPS Next Generation Delivery Vehicle All-Electric and Range-Extended Low-Floor Vehicle Recent Achievements Sep Won prototype contract to build and deliver six prototype units 2016 Sep Six purpose-built prototype vehicles delivered to USPS 2017 Mar USPS vehicle durability and field testing successfully completed 2019 Dec USPS issued the final RFP 2019 165,000-Vehicle, $6.3B USPS Contract Opportunity Work Ahead.

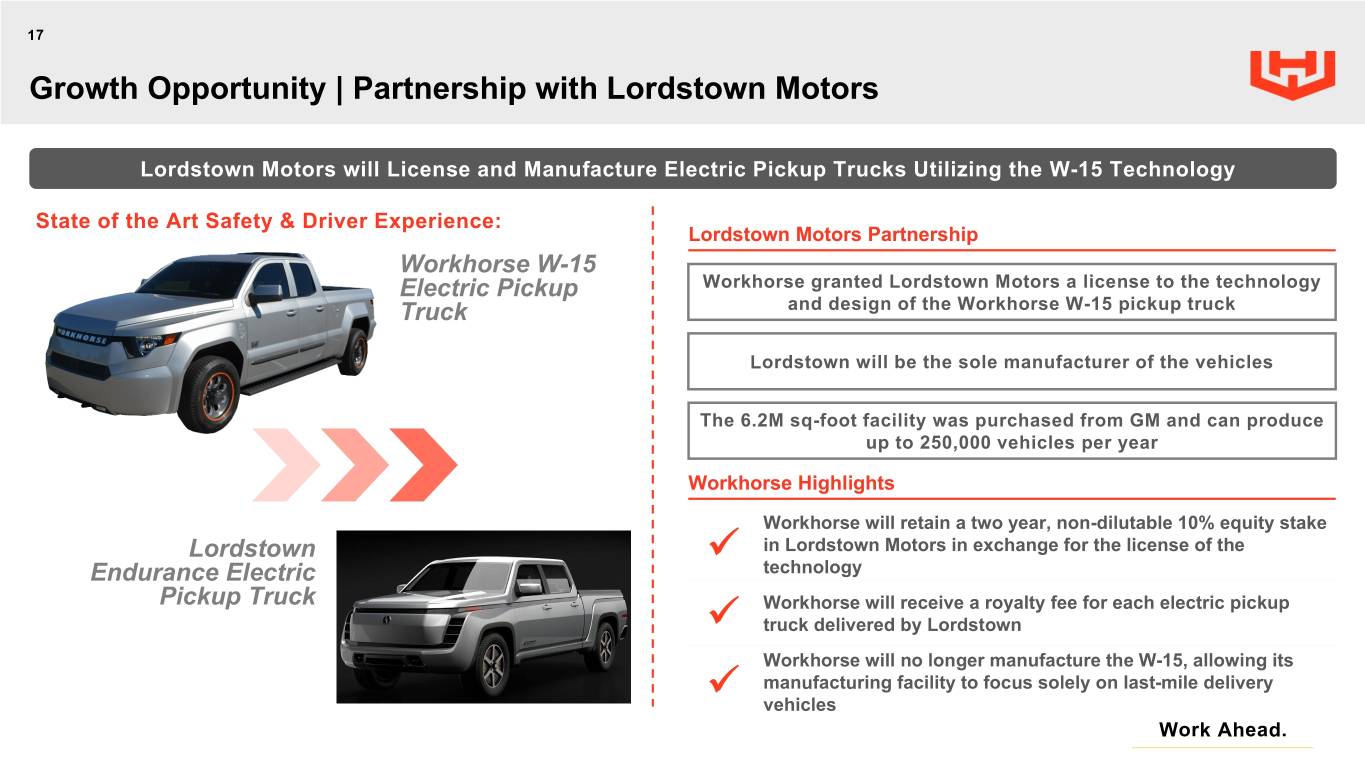

17 Growth Opportunity | Partnership with Lordstown Motors Lordstown Motors will License and Manufacture Electric Pickup Trucks Utilizing the W-15 Technology State of the Art Safety & Driver Experience: Lordstown Motors Partnership Workhorse W-15 Electric Pickup Workhorse granted Lordstown Motors a license to the technology Truck and design of the Workhorse W-15 pickup truck Lordstown will be the sole manufacturer of the vehicles The 6.2M sq-foot facility was purchased from GM and can produce up to 250,000 vehicles per year Workhorse Highlights Workhorse will retain a two year, non-dilutable 10% equity stake Lordstown in Lordstown Motors in exchange for the license of the Endurance Electric technology Pickup Truck Workhorse will receive a royalty fee for each electric pickup truck delivered by Lordstown Workhorse will no longer manufacture the W-15, allowing its manufacturing facility to focus solely on last-mile delivery vehicles Work Ahead.

18 Diverse Industry Experience & Expertise Duane Hughes, CEO . Senior-level executive with more than 20 years experience including direct business relationships in the automotive, advertising, and technology segments . Prior to joining Workhorse/AMP Electric Vehicles, Duane served as Chief Operating Officer for Cumulus Interactive Technologies Group . Prior to Cumulus ITG, Duane spent nearly fifteen years in senior management positions with Gannett Co., Inc., including his duties as Vice President of Sales and Operations Robert Willison, COO . Former partner and CTO at Ray Technology, and before that, was director of international operations and new business development at PDi Communication Systems . Previously held senior management positions at Hughes Aircraft and Texas Instruments; Director of Fleet Technology at Sysco . Earned a BSME, MSME, and PhD in Aero-Mechanical engineering, specializing in mechanics, robotics and spacecraft design at West Virginia, where he was also a NASA Fellow Steve Schrader, CFO . More than sixteen years of CFO experience in public and private companies in industries as diverse as manufacturing, health care, and utilities . Leadership experience in Strategic Planning, M&A, Corporate Finance and Investor Relations and held CFO roles at Fuyao Glass and Oncology Hematology Care (OHC) . Started career working for a group of utilities that are now part of Duke Energy as the Vice President and CFO of Cinergy's Regulated Business prior to Duke's acquisition in 2006 Don Wires, Director of R&D . Worked at P&G for 35 years where he was the first Technology Associated Director for Power, Control, & Information Systems . Co-author of several patents on machine automation and safety systems, and an early leader in developing a mechatronics approach to complex machine design at P&G . The first Engineering Technology Distinguished Alumni Graduate of the University of Cincinnati College of Engineering and Applied Science Richard Bastien, Director of Engineering . Licensed professional engineer and engineering manager with strong experience in mechanical and mechatronics engineering . Combined experience in all-wheel-drive drivetrain, powertrain integration, engine development, electronic control simulation and hydraulic hybrid development . Prior to Workhorse, Richard was the Chief Engineer at Bourns, Inc. and was responsible for managing the development of sensing products used in autonomous driving Bill Rutherford, Plant Manager . Responsible for launching nearly every Workhorse Custom Chassis and was integral in the development of each product change process . Experience in a variety of positions including materials, production, engineering, quality, industrial engineering and program management . Previously worked at Union City Body Co. and spent ten years at GE Aviation, where he held positions in supervision, production control, and materials management Work Ahead.